You use electrical systems every day, and understanding aluminum terminals importance is key to ensuring these systems are both safe and efficient. Aluminum terminals importance lies in their lightweight nature and cost-effectiveness, making them a popular choice in many applications. They also conduct electricity efficiently relative to their weight.

Advances in aluminum alloys have further highlighted aluminum terminals importance. These improvements have made aluminum more heat-resistant and stronger, which increases safety. As a result, aluminum wiring can now handle higher voltages and temperatures, maintaining its integrity and reducing fire risks.

The aluminum terminals importance is also seen in their ability to lower electrical resistance and minimize energy loss. While some people question the safety of aluminum, proper installation ensures that aluminum terminals provide reliable connections and rarely contribute to electrical fires.

Key Takeaways

Aluminum terminals do not weigh much and are not expensive. This makes them good for many electrical uses.

It is very important to install aluminum terminals the right way for safety. Always clean the connections well and use anti-oxidant compounds.

Aluminum terminals can help lower project costs a lot. They can save up to 70% when compared to copper terminals.

You need to check and take care of aluminum terminals often. This helps stop corrosion and keeps the connections working well.

Using aluminum terminals helps support green energy projects. They are often used in wind and solar power systems.

Aluminum Terminals Importance & Benefits

Conductivity and Performance

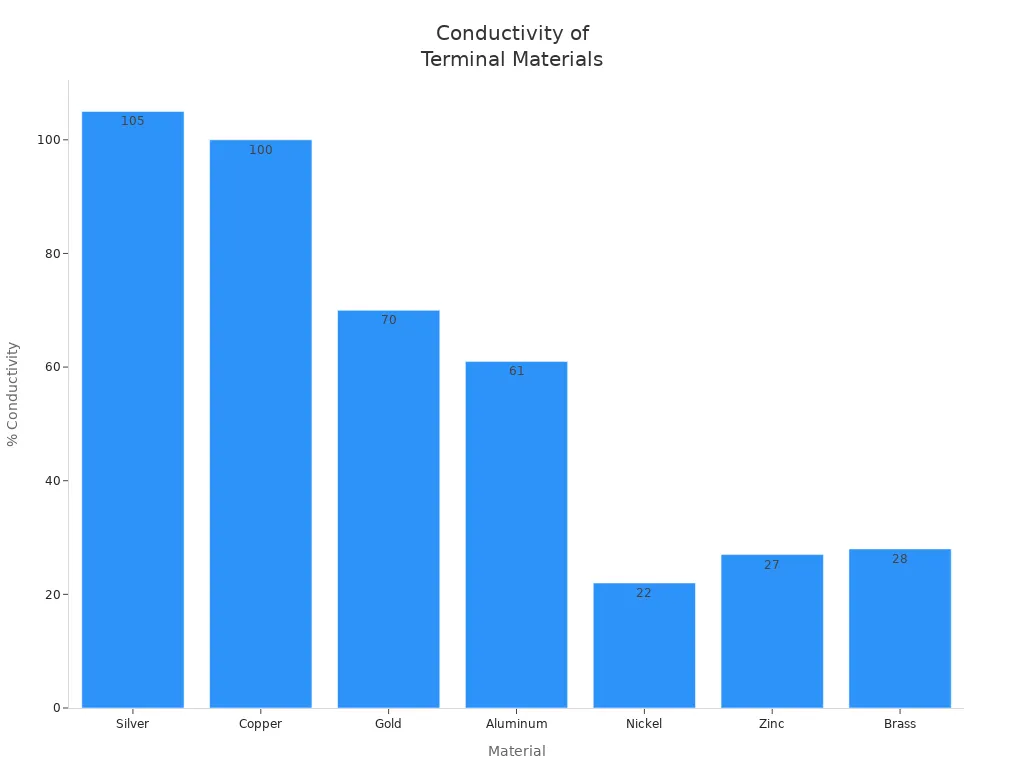

Safe and efficient systems need good electrical connections. Aluminum terminals are light and conduct electricity well. Silver and copper conduct better, but aluminum still works for most uses. The table below shows how aluminum compares to other materials:

Material | % Conductivity |

|---|---|

Silver | 105 |

Copper | 100 |

Gold | 70 |

Aluminum | 61 |

Nickel | 22 |

Zinc | 27 |

Brass | 28 |

Aluminum has about 61% of copper’s conductivity. This makes it useful for power lines and other systems. In high-current jobs, you should look at different features. The table below compares aluminum and copper:

Metric | Copper | Aluminum |

|---|---|---|

Electrical Conductivity | Excellent | Moderate |

Thermal Stability | High | Moderate |

Mechanical Strength | Superior | Limited |

Flexibility | Superior | Limited |

Corrosion Resistance | High | Needs protection |

Aluminum terminals importance is growing as new alloys get better. These new alloys are more flexible and resist rust. Modern alloys form a strong layer that keeps out rust. Some even have rare earth elements to make them safer. These changes help you build safer and longer-lasting connections.

Cost and Availability

You need to think about cost and performance. Aluminum terminals are cheaper than copper ones. The table below shows how much you can save:

Cost Component | Copper (USD/m) | Aluminum (USD/m) | Difference (%) |

|---|---|---|---|

Material Cost | 1.50 | 0.50 | Aluminum is 67% cheaper |

Installation Cost | 2.00 | 1.30 | 35% cost reduction |

Total Lifecycle Cost | 5.50 | 4.80 | Approximately 13% lower |

Aluminum is easier to find than copper. It is the third most common element in the Earth’s crust. Copper is number 25. This means aluminum terminals are easier to get and cost less. You save money on materials and installation, which helps big projects.

Note: The market for aluminum and copper terminal blocks will grow by 23% from 2025 to 2030. This shows more people see aluminum terminals importance in today’s electrical systems.

Lightweight Design

Aluminum terminals are much lighter than copper ones. Aluminum weighs about half as much as copper for the same job. The table below shows this:

Material | Weight Comparison |

|---|---|

Aluminum | 50% less than copper |

Copper | Heavier than aluminum |

This lighter weight gives you many benefits:

Easier to move and install, especially for big jobs.

Lower shipping costs because lighter loads use less fuel.

Less need for heavy supports in power lines.

Longer gaps between poles or towers, which saves money.

Aluminum terminals importance is clear in power grids and harnesses. You can put systems together faster and with less work. Aluminum also resists rust, so it is good for outdoor use.

Tip: Using aluminum terminals is better for the environment. Making aluminum uses less energy than copper, especially if you recycle. This helps make electrical projects greener.

Knowing these benefits helps you choose better for your systems. Aluminum terminals importance keeps growing as technology gets better and people want cheaper, efficient solutions.

Aluminum vs. Other Materials

Aluminum vs. Copper

Copper and aluminum are both used for electrical terminals. Copper lets electricity flow better than aluminum. Aluminum is lighter and costs less money. Here are some main differences from tests:

The DC resistance of 10 AWG copper-clad aluminum is about 11.28 milliohms. This is 6.69% lower than pure aluminum.

The AC impedance at 60 Hz for 10 AWG copper-clad aluminum is 11.60 milliohms. This is 6.93% lower than aluminum.

The total AC impedance at 60 Hz for 10 AWG copper-clad aluminum is 11.93 milliohms. This is 7.06% less than aluminum.

Copper terminals do not need much care. They do not rust easily, so you check them less. Aluminum terminals need to be checked often. You must make sure the connections are tight and clean. If you do not take care of aluminum wiring, it can cause house fires. Copper wiring is the safest and most trusted choice.

Aluminum vs. Other Metals

Some terminals are made from brass, stainless steel, or carbon steel. Aluminum is usually cheaper than stainless steel, brass, and copper. Carbon steel costs the least, but it is heavy and not good for electricity. Aluminum is best when you need something light. Brass costs more and its price changes with copper. Stainless steel costs the most, but it is very strong and lasts long.

When you connect copper and aluminum wires, use copper-aluminum lugs. These bimetal cable lugs are made with special welding. This stops rust and makes the connection last longer. Bimetallic terminals help connect copper and aluminum safely. They keep your system working well.

Tip: Always use the right connectors for mixed metals. This stops rust and keeps your electrical system safe.

Aluminum terminals are important when compared to other materials. They give you a good mix of price, weight, and how well they work, especially if you use the right connectors.

Practical Use and Safety

Installation Best Practices

It is important to install aluminum terminals the right way. This helps your system work well and stay safe. First, clean the conductor to get rid of oxidation. Then, put on an anti-oxidant compound to stop more oxidation. Use the tools and torque that the maker says to use. Strip the conductor to the correct length. Push it all the way into the terminal. After one or two days, check and tighten the connection again.

Clean the conductor well.

Add anti-oxidant compound.

Use the right tools and torque.

Strip to the correct length and insert fully.

Tighten again after 24-48 hours.

Some connectors already have conductor termination compound inside. If not, use the compound the connector maker suggests.

Picking the right connector matters too. For example, partial tension wire jumper splices work with aluminum wires. Compressed conductor sizes are made for certain aluminum wires. These connectors help you make strong and safe connections.

Description | |

|---|---|

Partial tension wire jumper splices | Rated for 40% tension, good for aluminum wire connections. |

Compressed conductor sizes | Made for certain aluminum wire types for secure connections. |

Corrosion and Oxidation

Aluminum reacts with oxygen in the air. This makes a layer called aluminum oxide. Wet air, saltwater, pollution, and strong chemicals can make this happen faster. You can stop problems by cleaning and taking care of your terminals. Use pressure washing, chemical cleaning, or steam cleaning to get rid of oxidation. Regular cleaning keeps your connections safe and strong.

The oxide layer on aluminum helps protect it. But if chloride ions are around, pitting corrosion can happen. This means you should check your terminals often, especially in tough places.

Safety and Reliability

Aluminum terminals can get bigger and smaller when temperatures change. This can make connections loose over time. Loose connections can get hot and may cause fires. The CPSC says homes with old aluminum wiring have a higher fire risk than homes with copper wiring.

Aspect | Aluminum Terminals | Copper Terminals |

|---|---|---|

Overheating risk | Can overheat if not installed right | Lower chance of overheating |

Connection stability | Less steady over time | More steady when used a lot |

Fire hazard | Old problems show more risk | Usually safer |

You can lower these risks by using connectors that follow the rules and best steps. This shows why aluminum terminals are important for keeping electrical systems safe and reliable.

Applications of Aluminum Terminals

You can find aluminum terminals in many places. These terminals connect wires and move electricity safely. Their special features make them a good choice in many industries.

Power Transmission and Distribution

Aluminum terminals are used in power lines and grids. They are common in big transmission projects. Engineers pick aluminum for several reasons:

Aluminum is light, so it is easy to install. You do not need many heavy supports.

It costs less than copper, which saves money on large jobs.

Aluminum does not rust easily because it forms a strong oxide layer.

It can carry enough current over long distances without getting too hot.

These features help keep your electricity safe and not too expensive.

Renewable Energy Systems

Aluminum terminals are important in green energy. You see them in wind and solar power systems.

Wind turbines use aluminum in blades, towers, and connectors. The light weight helps the turbines spin and stay up.

Solar systems use aluminum for frames and brackets. This keeps the panels strong but not heavy.

Aluminum’s lightness is great for building big solar farms and wind parks.

Here is how aluminum helps renewable energy grow:

Wind power uses a lot of aluminum for each kilowatt made.

Wind farms have special aluminum parts made for them.

As solar and wind get better, more aluminum will be used.

Other Common Uses

You also see aluminum terminals in:

Car wiring harnesses

Airplane electrical systems

Home electrical panels

These uses show that aluminum terminals make systems lighter, safer, and work better.

Tip: Choosing aluminum terminals helps build energy systems that are strong, save money, and are ready for the future.

Aluminum terminals work well, cost less, and are simple to put in. You can save up to 70% on materials. Projects are lighter and finish faster with aluminum terminals.

Aluminum terminals only work well if you install them right. If connections get loose from heat changes, they can get too hot and might start a fire.

To keep your system safe and working, try these tips:

Use approved connectors like AlumiConn™ when fixing things.

Make sure connections are tight and look for any heat damage.

Have trained electricians check your system often.

Picking aluminum terminals helps you make electrical systems that are safe and work well.

FAQ

What makes aluminum terminals a good choice for electrical connections?

Aluminum terminals are lighter than copper ones. They cost less money, too. Most jobs can use aluminum terminals. You can move and install them easily. Big projects save money with aluminum terminals.

How do you prevent corrosion on aluminum terminals?

Clean the terminals before you put them in. Use anti-oxidant compounds on them. Check the connections often to make sure they are safe. Keep the terminals dry and away from strong chemicals. These steps help stop corrosion from happening.

Are aluminum terminals safe for home wiring?

Aluminum terminals are safe if you use them right. Always use connectors that are approved for aluminum. Make sure the connections are tight and secure. Have a licensed electrician check your wiring to stay safe.

Can you connect aluminum terminals to copper wires?

You need to use bimetal lugs for this job. These connectors keep the connection strong and stop corrosion. Never twist aluminum and copper wires together without the right connector.